by IntelliTrans | Jun 18, 2019 | TMS

Let’s face it, many TMS products share the same features nowadays. And, with all the noise in the market, it can be difficult to understand what differentiates providers. So, what makes IntelliTrans different? Our dock scheduling feature is unique and so...

by IntelliTrans | Oct 10, 2018 | TMS

Our goal at IntelliTrans is to drive successful outcomes for shippers, and helping carriers and 3PLs better serve our shipper customers is a key part of that mission. That’s why we’ve released an API suite to extend IntelliTrans TMS functionality to carrier and 3PL...

by IntelliTrans | May 29, 2018 | TMS

2018 – the year of the capacity crunch – has been a challenging year for freight shippers. Not only have they faced significant upward cost pressure, but also declines in service. And, these market dynamics likely won’t let up anytime soon as...

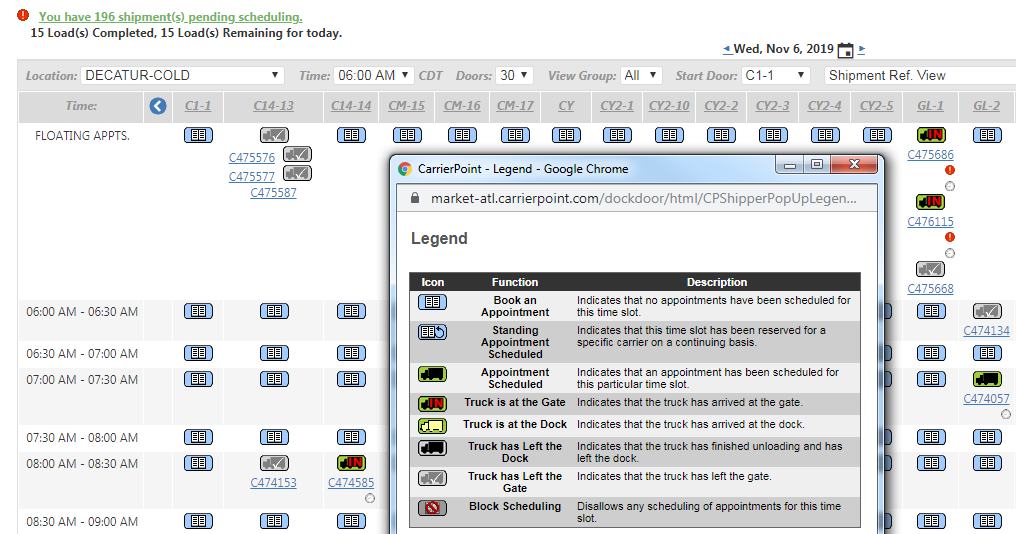

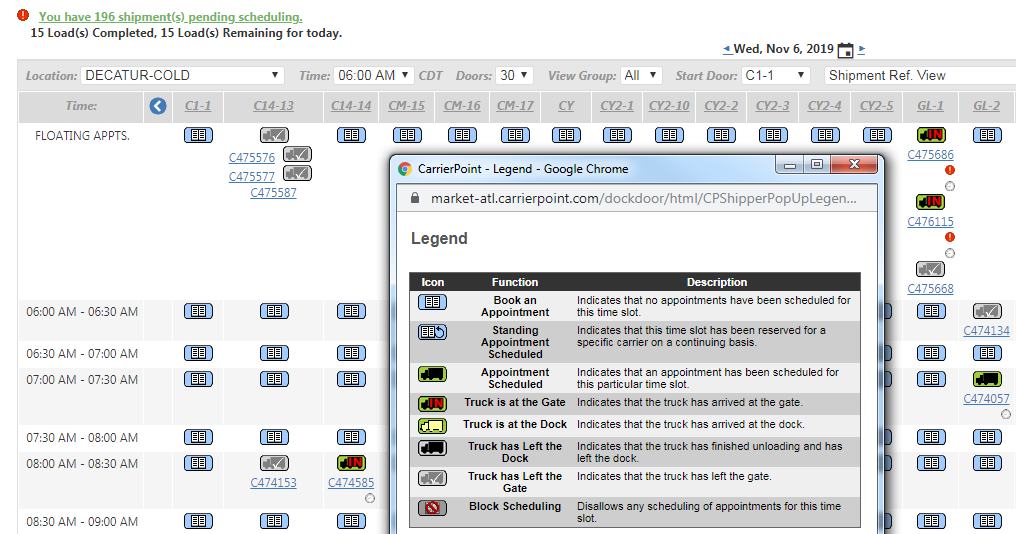

by IntelliTrans | Sep 13, 2015 | TMS, Visibility

The Challenge The trucking industry loses an estimated $1.3 billion a year waiting at customer facilities to pick up or deliver cargo. One of the top reasons for driver turnover is wasted time sitting at warehouse docks; for truckers who get paid by the...

by IntelliTrans | Jan 13, 2015 | TMS

Our SaaS-based transportation management system (TMS) is fully integrated with DAT load boards, enabling shippers and third-party logistics providers (3PLs) to use a single system to manage contract freight, private fleets, and spot market moves. By integrating our...